Custom Optical Lens and Mold Development

Honju Optics has been deeply engaged in the optical mold manufacturing field for over a decade. We have assembled a team of experienced optical engineers and are equipped with advanced optical testing equipment to provide complete mold manufacturing solutions and high-quality SKD services for lighting fixtures.

Phase 1: Requirements Matching and Technical Assessment

Upon receiving a customer’s request, Honju Optics’ professional team promises to respond quickly within two hours and initiate the project matching process. We use a standardized requirements analysis form and conduct multiple rounds of in-depth discussions with the customer to gain a comprehensive understanding of the product requirements:

- Specific optical performance requirements: light distribution curve, illuminance distribution, beam angle, etc.

- Required light source: model, brand, etc.

- Operating environment conditions: temperature range, humidity requirements, weather resistance, etc.

- Structural size restrictions: installation space, interface method, weight requirements, etc.

- Material selection preferences: optical-grade PMMA, PC, or special materials.

- Expected scale and timeline for mass production.

Based on this information, our engineering team will provide a detailed technical feasibility analysis report within 48 hours, including material selection recommendations, process feasibility assessment, risk assessment, and a preliminary project implementation plan and timeline.

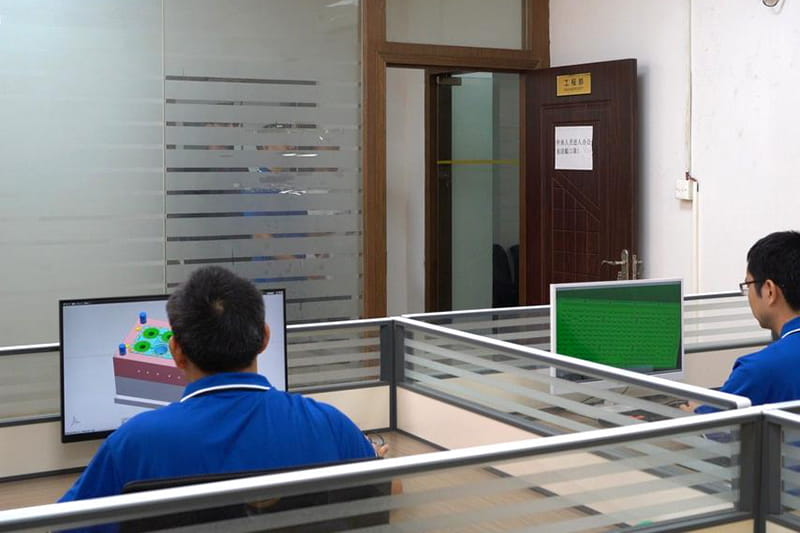

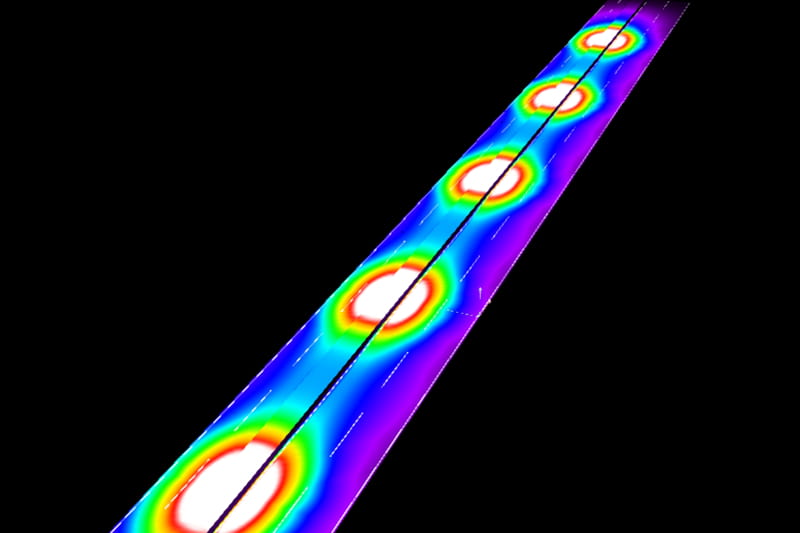

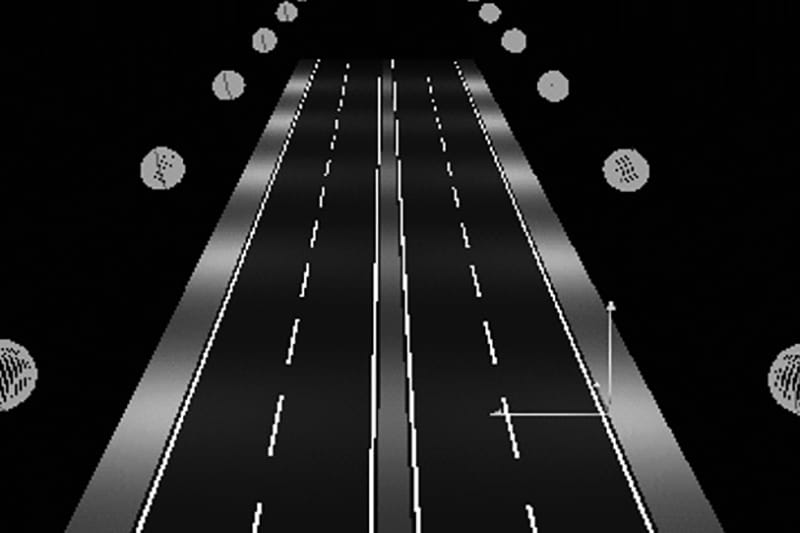

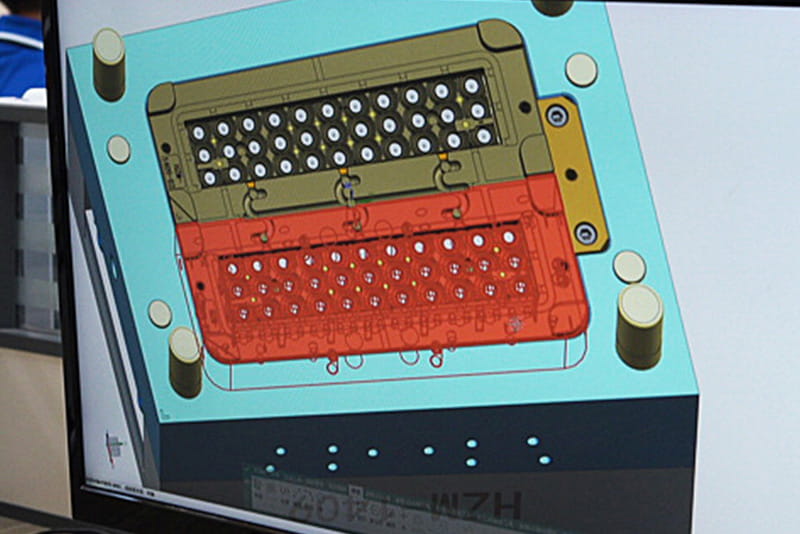

Phase 2: Optical Design and Simulation Verification

Honju Optics’ optical design team utilizes Zemax optical design software to perform precise optical system design, optimizing optical surface shapes and structural parameters to ensure the optical performance specifications meet customer requirements.

LightTools also performs ray tracing and illumination simulation to verify the rationality and effectiveness of the optical design.

In addition, DIALux is used to simulate real-world lighting effects, allowing customers to intuitively understand the final lighting effect before actual production.

During this process, we also conduct detailed tolerance analysis and evaluate the feasibility of the manufacturing process to ensure that the design meets both optical performance requirements and has good manufacturability.

Finally, we provide a complete design report, including optical design drawings, 3D model files, simulation analysis results, and expected optical performance data.

Phase 3: Test Mold Fabrication and Verification

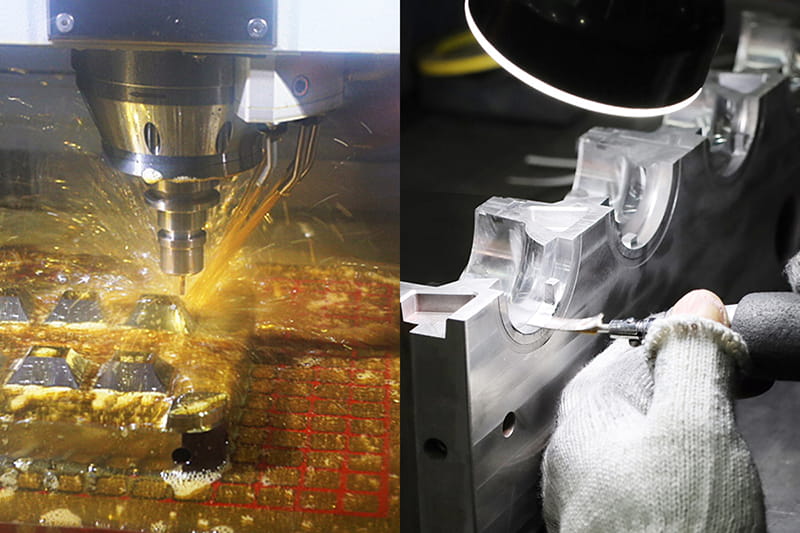

- First, we engage in test mold fabrication, completing the entire process from mold design, precision machining, mold assembly, and initial mold trials within a 7-day cycle.

- After the trial mold is completed, we will produce the first batch of samples and conduct comprehensive testing and verification. We use a goniophotometer to precisely measure the light distribution curve and beam angle, and an integrating sphere to measure optical parameters such as luminous flux and luminous efficacy. We also conduct rigorous environmental reliability testing, including high- and low-temperature cycling (-40°C to 120°C), UV aging testing, and damp heat testing. Based on the test results, our engineering team will conduct detailed data analysis and, if necessary, make design optimizations and mold adjustments. Through re-testing and verification, we ensure that the product fully meets design requirements.

- Finally, we will provide a complete test report and work with the customer to complete sample approval and sign-off.

Phase 4: Custom Development of Large-Scale Molds

Once the trial mold is approved by the customer, Honju Optics will begin custom development of the mass production mold. This phase primarily includes:

- Optimizing the mold structure, adopting a multi-cavity design to improve production efficiency;

- Precision machining using high-quality mold steel to ensure mold accuracy and longevity;

- Professional heat treatment to improve mold wear resistance and service life;

- Precision surface treatment, including polishing and chrome plating, to ensure product surface quality;

- Finally, through multiple mold trials, we continuously optimize mold and process parameters to ensure stable mass production capabilities and a service life of over one million cycles.

Honju Optics ensures a full 25-day mass production mold development cycle. During this period, we will regularly report progress to our customers to ensure timely project completion.